What are the advantages of using Tube-Lock®?

Tube-Lock® enables to you build a flexible, safe scaffold consisting of light components. By combining simplicity and strength, the Tube-Lock® system can be erected and dismantled faster than traditional tube scaffolds. And this is just one of the many advantages. Curious to know more about our Tube-Lock® concept and how it can benefit you? We have listed 10 advantages of using the Tube-Lock® concept below.

1. You need fewer parts

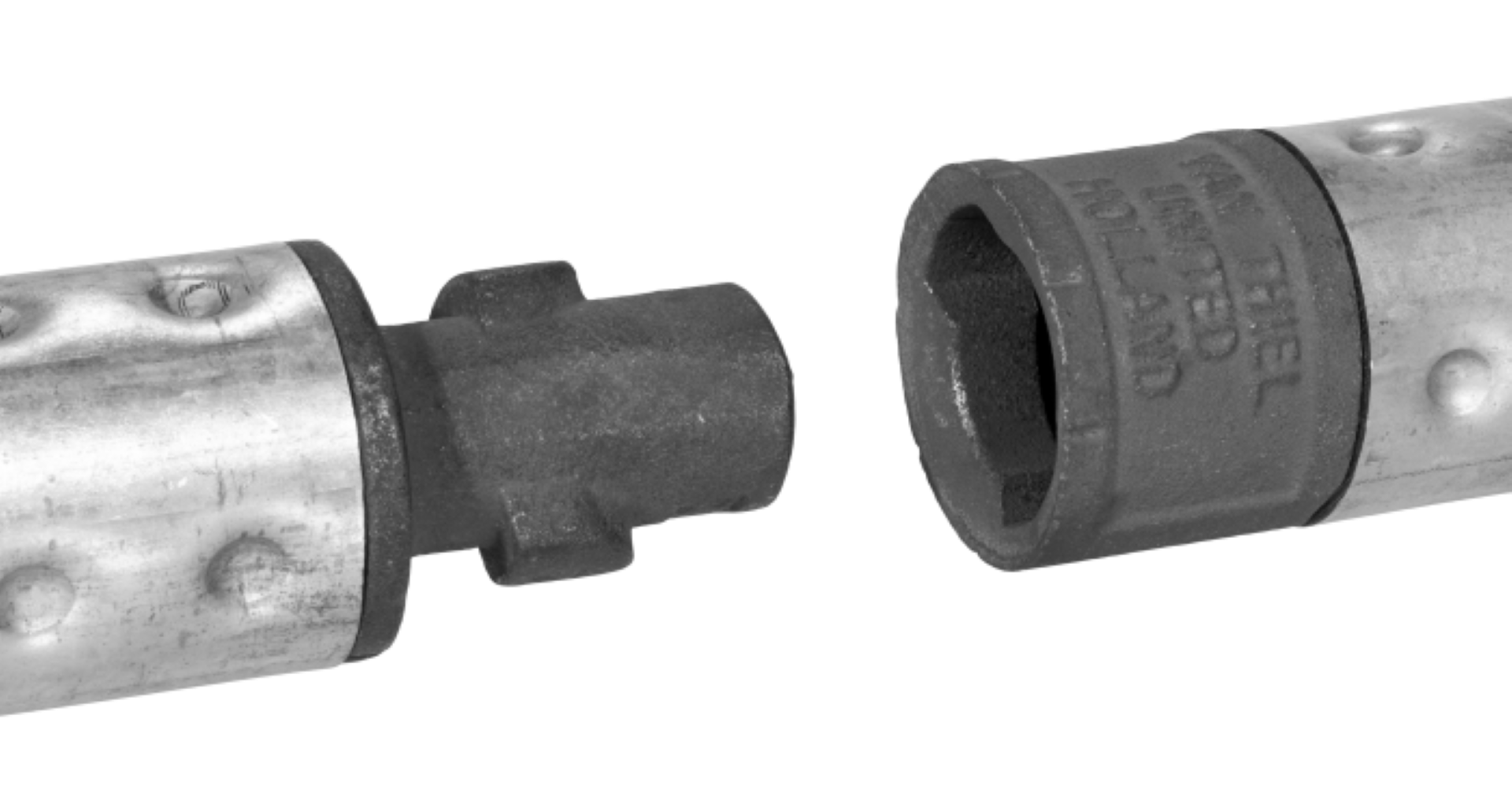

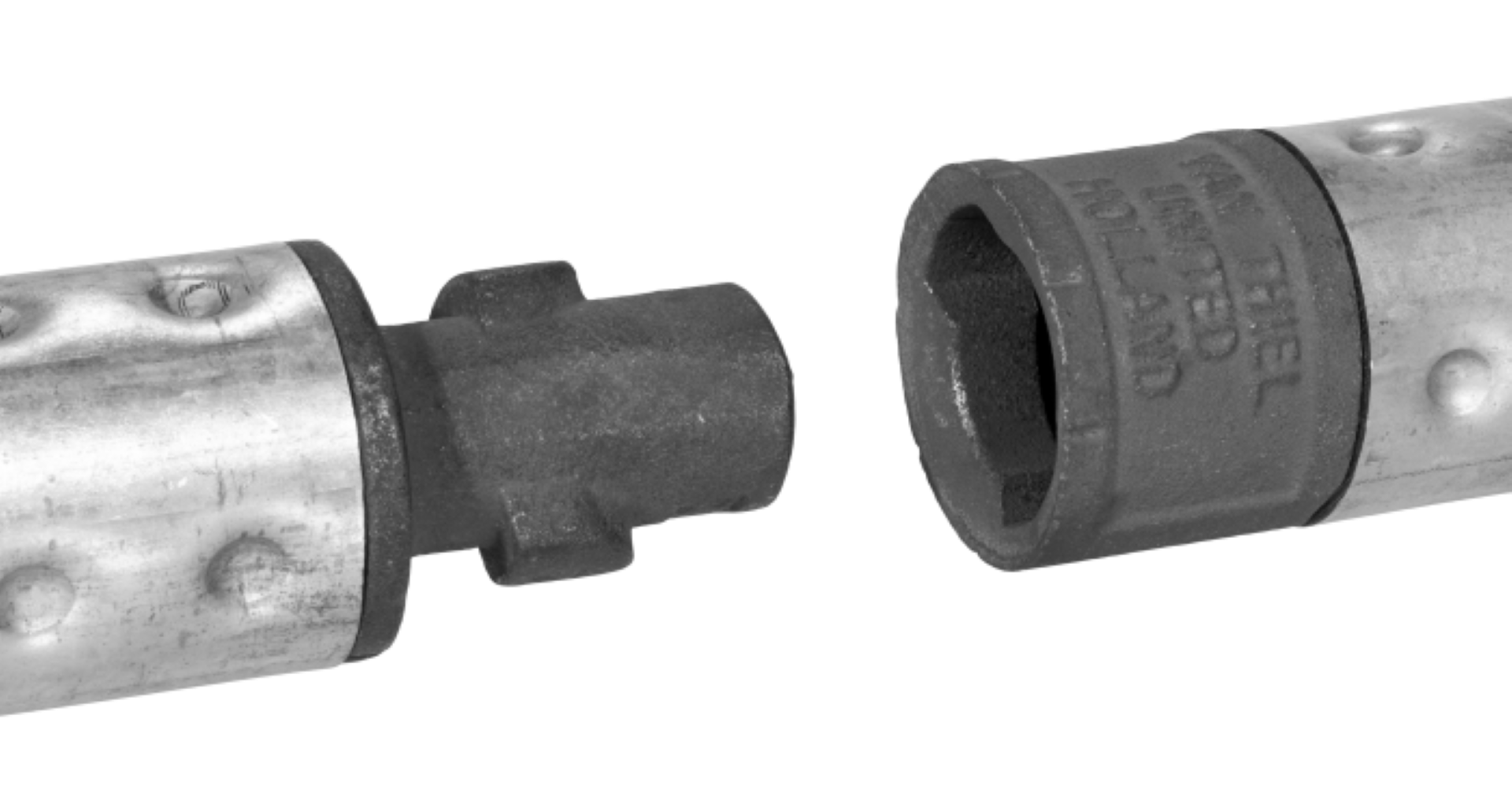

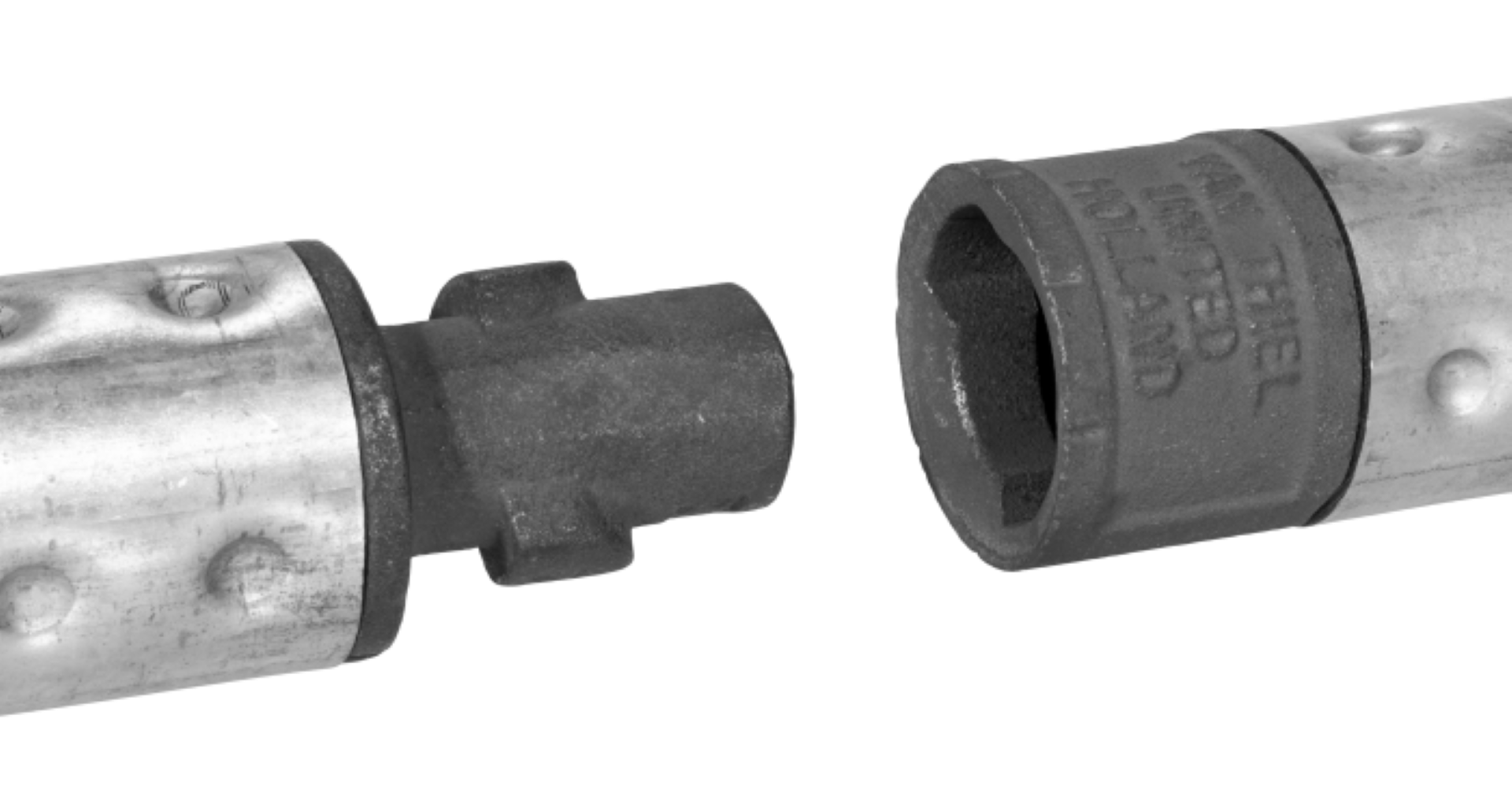

Two tubes fitted with Tube-Lock® can be connected together simply by twisting them.

This means you only need the following parts:

- Tube with Tube-Lock® fitting ♂ + ♀

- Tube with Tube-Lock® fitting ♂ + ♀

Number of required parts: 2

To be able to connect two tubes in the traditional tube and coupler way, you need the following:

- Tube

- Tube

- Joint coupler

- Spigot

Number of required parts: 4

This means using the Tube-Lock® system reduces the amount of parts you need by 50%.

2. Tube-Lock® assemble faster

The average time it takes to connect the Tube-Lock® tubes is 2 seconds. No tools are required. It is the twisting motion that will lock the two pipes together.

The average time it takes to connect two tubes in the traditional way is 35 seconds.

Additionally, you need a ratchet wrench to be able to fix the bolts.

This means that two Tube-Lock® pipes can be connected around 15 times faster than two pipes without Tube-Lock® fittings.

3. Tube-Lock® will give you a smooth tube connection

When using Tube-Lock®, you do not need a sleeve coupler to connect the two tubes together. This leaves you with a “smooth” pipe over the total length and width of the scaffold. Therefore it is possible to attach a right angle coupler or a swivel coupler on or just above or below the connection of the two pipes.

When using the tube and coupler system, it is not possible to attach a right angle coupler or a swivel coupler at the connection point.

Therefore Tube-Lock® provides you with more flexibility when it comes to building the scaffold.

4. Limiting storage space and time

With two standard lenghts of the Tube-Lock® system, you can create all possible lengths. When you have 2 and 3 meter pieces in stock, you can create the following tubes:

- Tube 2m = 2m

- Tube 3m = 3m

- Tube 4m = 2m + 2m

- Tube 5m = 3m + 2m

- Tube 6m = 3m + 3m

Because connecting two tubes takes less than two seconds with the Tube-Lock® system, connecting two tubes is no longer an issue.

When comparing this to the traditional tube and coupler system you will need 5 different tubes to achieve the same lenghts. Additionally you will need a joint coupler and spigot to be able to make the connection between the two tubes.

5. Logistical advantages

There are plenty of logistical advantages for the Tube-Lock® system:

- Shorter tubes are easier to handle.

- Because they are easier to handle, there is less risk involved and therfore less damage occurs when transporting the tubes.

- Because the tubes are of the same length and you don’t need additional parts to connect them, there is no lost space on the truck.

- Less seperate parts means less chance of loss and/or theft.

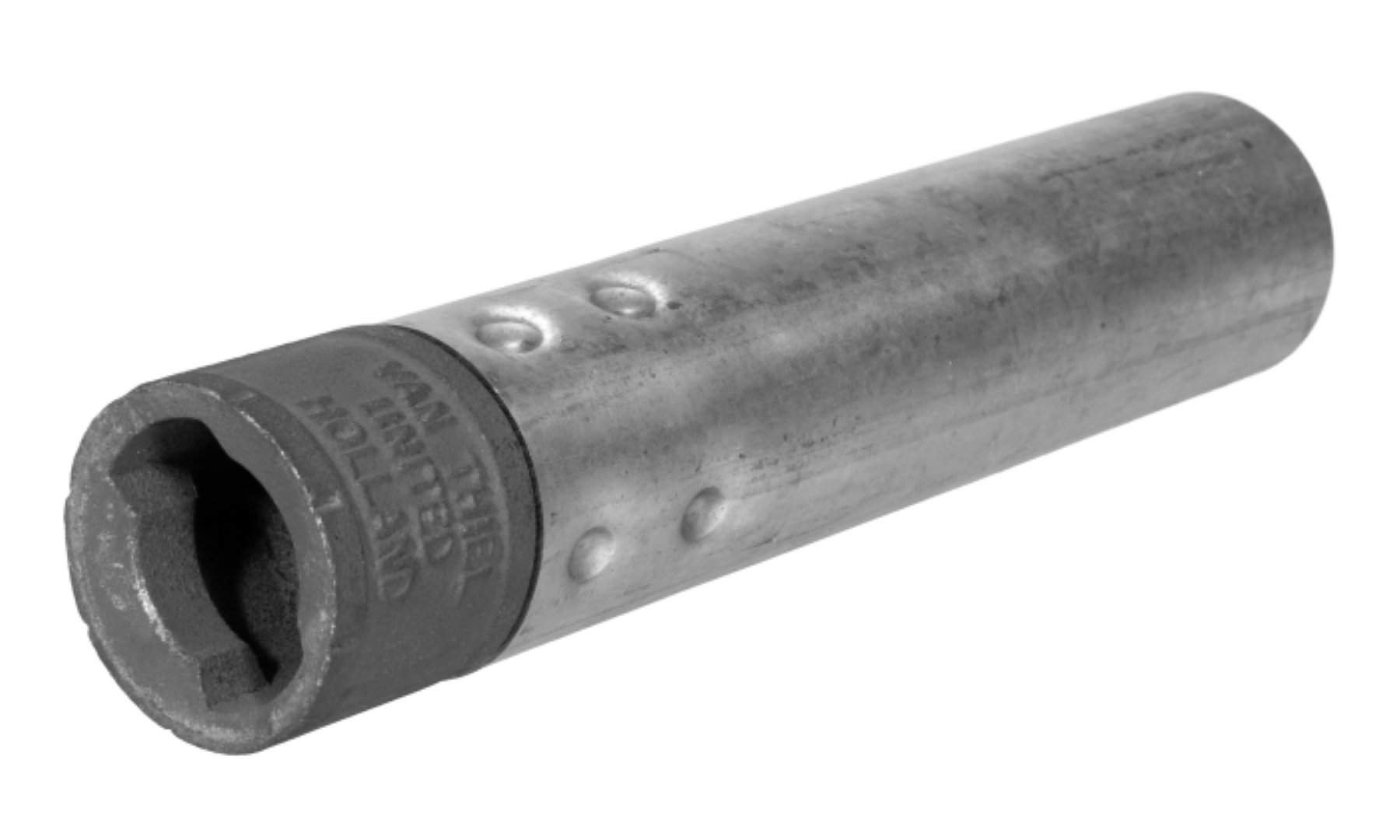

6. The ends of the tubes are closed

The ends of the tubes are closed by the Tube-Lock® fittings that are installed inside of the tube.

This means no sand, wool, other building materials or waste can accumulate inside of the tube.

7. Increased personal safety

Through using shorter parts (maximum 3 meters) the physical load for the workers is strongly reduced. The average Tube-Lock® tube of 3 meter weighs 12 kgs. The average steel tube of 6 meters weighs 24kgs.

Because of the limited lenghts (2m and 3m), handling the Tube-Lock® tubes is easier as well. This means less risk regarding damage or personal injury.

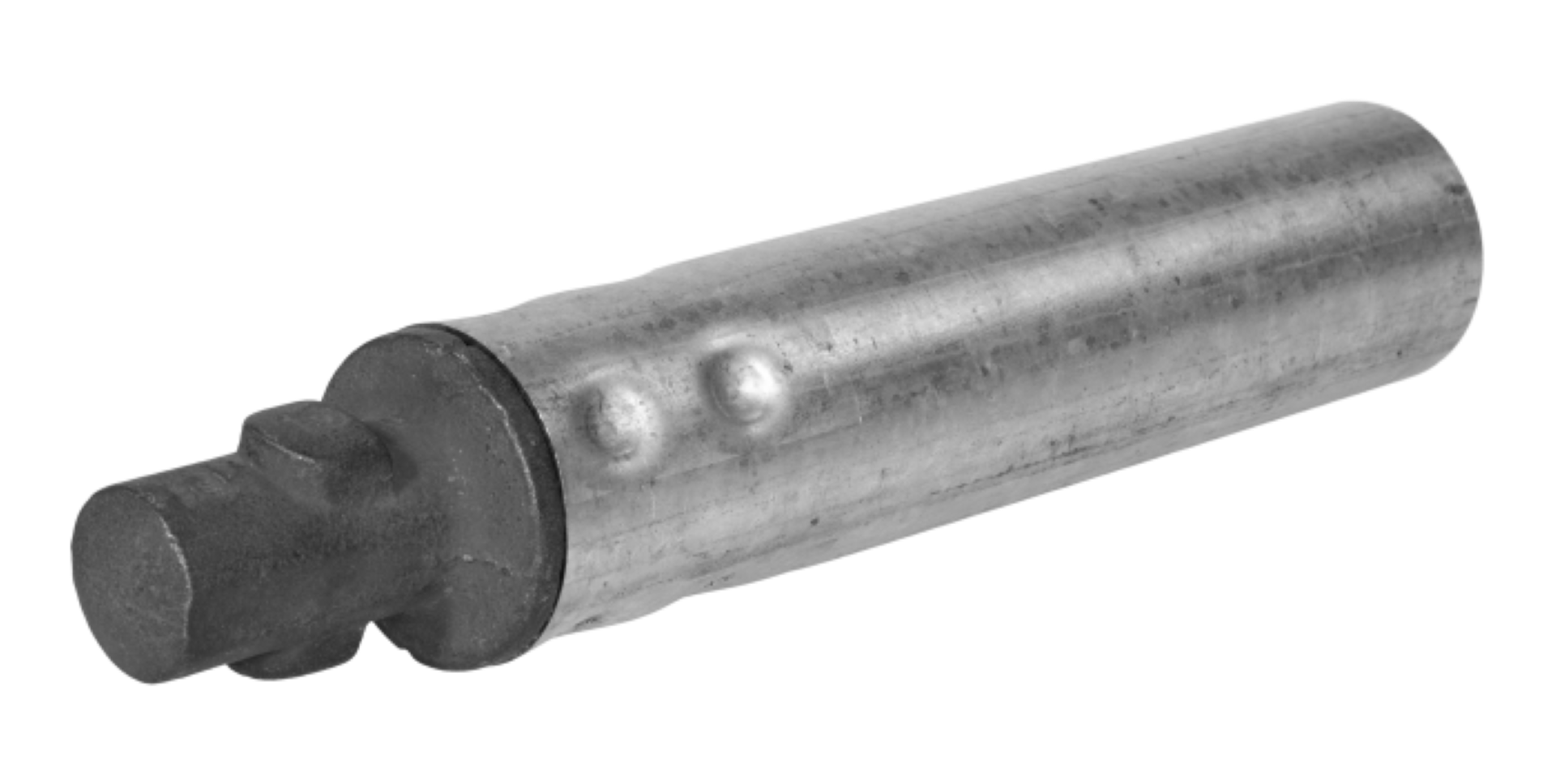

8. Visible locking

When fixing two tubes by giving them a little turn by hand, there is a visible check by means of marks, to check the state of the tube.

If it’s possible to turn the lowest mark over one of the both highest marks, the tube has damage.

The lowest mark is positioned in between the both highest marks, this is an indication that the tube is well locked.

9. You can use your current tubes

We offer the possibility to convert your used tubes to tubes with Tube-Lock® ends.

Before the Tube-Lock® ends will be fitted, the tubes will be visually inspected, aligned and cut to your desired length.

We also offer the opportunity to have your tubes marked in your company colours so you can recognise them everywhere.

Please contact us for more information about the possibilities and to hear the terms and conditions!

10. Technical advantages

The technical advantages of the Tube-Lock® system are overwhelming:

Tube-Lock® fittings may be submitted to pull force, making it possible to use Tube-Lock® in a suspended scaffold.

Additionally, Tube-Lock® connections can handle direct vertical pressure as well.

Sounds convinving. And now?

Please contact us to discuss the possibilities. We would be happy to discuss all opportunities we can offer.

You can reach us by sending an e-mail to info@thiel.nl or by using the contact form on our website.